Explore new trends in Precision aluminum casting for aerospace applications

Recognizing the Relevance of Aluminum Spreading in Modern Manufacturing Processes

Aluminum casting has actually emerged as a vital component in modern production. Its sturdy and light-weight nature contributes considerably to various markets, from auto to electronics. Furthermore, improvements in casting methods improve manufacturing performance and high quality. As makers seek innovative remedies, the role of aluminum spreading in sustainability becomes increasingly significant. This discussion will explore the diverse significance of light weight aluminum spreading and its ramifications for the future of production. What exists ahead in this progressing landscape?

The Advantages of Light Weight Aluminum Casting in Production

Light weight aluminum casting offers numerous benefits that improve its appeal in modern manufacturing processes. One significant benefit is its light-weight nature, which brings about decreased energy consumption and boosted fuel efficiency in transport applications. Furthermore, aluminum's outstanding deterioration resistance extends the life-span of actors products, making them more resilient in different settings. The product additionally promotes elaborate layouts and intricate geometries, allowing producers to produce elements that fulfill accurate specs.

Additionally, aluminum casting flaunts a relatively low melting point, which conserves power during the production procedure. This feature also allows rapid cycle times, enhancing overall performance. The recyclability of aluminum contributes to sustainability initiatives, as recycled aluminum requires substantially less energy to procedure compared to main light weight aluminum. Collectively, these advantages placement light weight aluminum casting as a vital method in contemporary manufacturing, catering to the demands for efficiency, performance, and environmental responsibility.

Applications of Light Weight Aluminum Spreading Across Industries

While numerous materials are employed in manufacturing, aluminum spreading has come to be a pivotal technique throughout several sectors because of its flexibility and functionality. This procedure is widely used in the auto market for producing lightweight engine blocks, transmission instances, and various elements that boost fuel effectiveness. In the aerospace sector, aluminum spreading is vital for creating elaborate components that require high strength-to-weight proportions, adding to enhanced airplane efficiency.

Furthermore, the electronics industry relies upon aluminum castings for heat sinks and housings, where thermal monitoring is essential for gadget durability. The building market likewise benefits from aluminum casting in the kind of building elements and structural elements that incorporate visual appeal with toughness. Furthermore, the consumer goods sector utilizes aluminum spreadings for kitchenware and sporting equipment, leveraging the material's excellent corrosion resistance and visual surface. In general, aluminum spreading serves as a keystone in contemporary manufacturing, sustaining varied applications throughout different fields.

The Duty of Aluminum Spreading in Sustainability

Sustainability has actually come to be a focal factor in manufacturing techniques, and aluminum casting plays a vital duty in advertising eco-friendly remedies. The process of aluminum casting is naturally lasting due to the product's recyclability. Aluminum can be recycled several times without shedding its homes, considerably minimizing energy intake and resources needs. This recycling process takes in only around 5% of the energy needed for primary light weight aluminum production, causing a significant decline in carbon discharges.

Additionally, light weight aluminum spreading helps with the production of light-weight elements, which add to energy effectiveness in numerous applications, particularly in the auto and aerospace markets. Lighter lorries take in less fuel, additional minimizing environmental effect. In addition, improvements in casting methods are maximizing product utilization, minimizing waste in making processes. As industries seek to align with sustainability goals, light weight aluminum spreading arises as a viable service, supporting a circular economic climate and promoting accountable manufacturing methods

Technical Innovations in Aluminum Casting Techniques

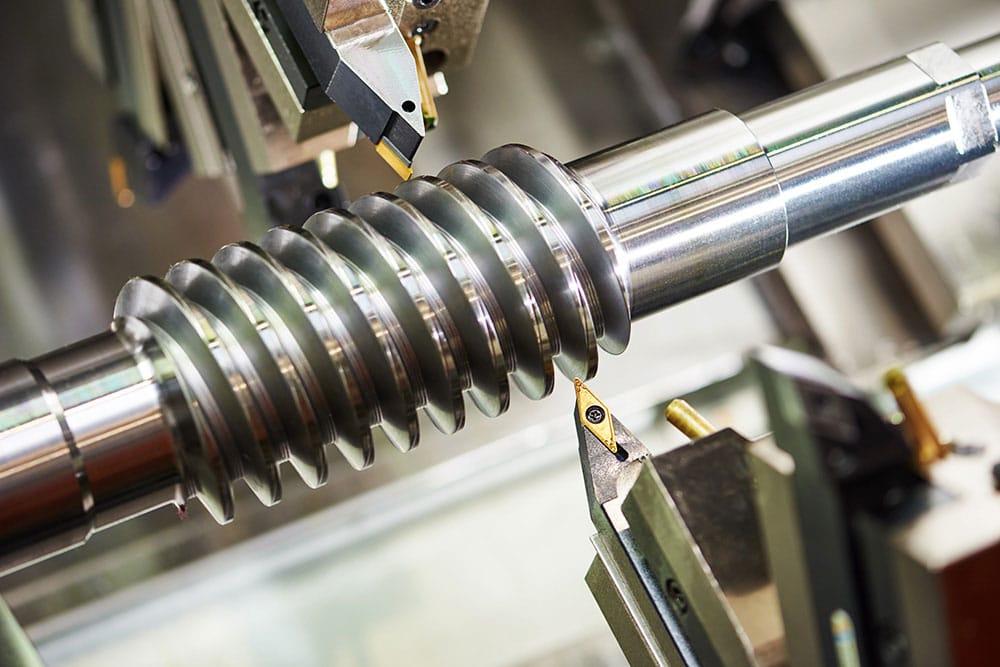

As industries develop, the adoption of innovative innovations in light weight aluminum spreading methods has transformed making processes. The integration of computer-aided design (CAD) and computer-aided production (WEB CAM) systems boosts accuracy and performance, enabling complicated geometries that were previously challenging to generate. Advanced melting and spreading methods, such as die spreading and investment casting, have boosted the top quality of light weight aluminum parts, reducing and decreasing issues waste. Additionally, the introduction of automated systems and robotics in casting procedures Get the facts has structured process and enhanced performance. These innovations additionally allow real-time tracking and information analytics, assisting in better decision-making and top quality control. Additionally, the growth of new alloys and warmth treatment processes has broadened the performance capabilities of actors light weight aluminum items. Jointly, these technological innovations not only enhance production efficiency but additionally add to the sustainability of light weight aluminum spreading in modern-day manufacturing.

Future Patterns in Light Weight Aluminum Spreading and Its Influence On Advancement

Emerging patterns in aluminum spreading are poised to improve the production landscape, driving development throughout different industries. One substantial trend is the combination of innovative automation and robotics, which enhances accuracy and efficiency in production procedures. my blog In addition, the rise of additive manufacturing methods is enabling a lot more complex styles, reducing material waste and manufacturing time. As sustainability comes to be a priority, the market's concentrate on reusing aluminum and using eco-friendly methods is anticipated to expand, straightening with international environmental goals.

The advancement of wise spreading technologies, including real-time monitoring and information analytics, is established to improve high quality control and operational efficiency. These improvements will certainly promote the production of lighter, more powerful, and extra durable light weight aluminum elements, providing to markets such as vehicle and aerospace. Eventually, these trends will certainly not just enhance manufacturing procedures yet additionally motivate new applications of aluminum casting, promoting a culture of development and adaptability out there.

Often Asked Concerns

What Is the History of Light Weight Aluminum Spreading in Manufacturing?

Just How Does Light Weight Aluminum Spreading Compare to Various Other Steels?

Aluminum casting deals advantages such as lightweight residential properties and rust resistance compared to various other metals. aluminum casting. It enhances and promotes complicated shapes power efficiency, making it a recommended option in various production applications over much heavier alternatives like steel or iron

What Are the Usual Problems in Light Weight Aluminum Casting?

Usual problems in light weight aluminum casting consist of porosity, shrinkage, misruns, and inclusions. These problems Check Out Your URL can arise from inappropriate pouring methods, inadequate mold and mildew layout, or infected products, bring about reduced structural stability and performance of the final product.

Exactly how Is the Top Quality of Aluminum Castings Tested?

The quality of aluminum castings is evaluated with techniques such as visual examinations, dimensional dimensions, non-destructive testing methods, and mechanical residential property assessments, making sure that they fulfill specified requirements for performance and structural stability.

What Are the Safety Steps in Aluminum Spreading Processes?

Safety procedures in aluminum casting processes include using individual protective devices, correct ventilation systems, normal equipment maintenance, training employees on hazards, and applying strict emergency situation protocols to reduce threats associated with heats and liquified steel.

The recyclability of aluminum adds to sustainability initiatives, as recycled aluminum calls for substantially much less energy to process contrasted to primary aluminum. While different products are employed in production, light weight aluminum spreading has become a crucial approach across numerous sectors due to its flexibility and performance. Advanced melting and spreading approaches, such as die spreading and financial investment spreading, have improved the high quality of light weight aluminum components, minimizing defects and reducing waste. Arising fads in light weight aluminum spreading are positioned to improve the manufacturing landscape, driving development across various industries. Aluminum casting has actually advanced since the late 19th century, initially creating with the intro of light weight aluminum as a light-weight metal.